Processing

WINBOSS Industrial Co., Ltd. excels in the realm of NBR foam rubber manufacturing, showcasing a remarkable processing advantage through its diversified array of techniques. These versatile technical methods encompass skiving, die cutting, adhesive, sewing, and vinyl-coating, among others. Such refined processing skills not only demonstrate our profound mastery of the production process but have also earned us an exceptional reputation in the market. The following will elaborate on our exceptional strengths in these various diversified processing techniques.

Exemplary Application of Adhesive Process

We extensively utilize adhesive technology in the production of NBR foam rubber. This process securely bonds the foam with various base materials, meeting diverse application needs. The skillful application of adhesive backing not only enhances the stability and durability of the products but also provides customers with a wider range of application options.

Superior Effects of Vinyl Coating Process

We employ our vinyl coating technology on certain products, which not only enhances the visual appeal of the products but also increases their abrasion resistance and weather resistance. The application of this process injects more artistic and creative elements into the products, making them more valuable and competitive.

Precision in Skiving Technology

We employ cutting-edge technology to craft NBR foam sheets into various shapes and thicknesses, according to the specific needs and specifications of our clients. This precise cutting technique ensures the accuracy and consistency of our products, thereby guaranteeing that they fully meet our clients' expectations.

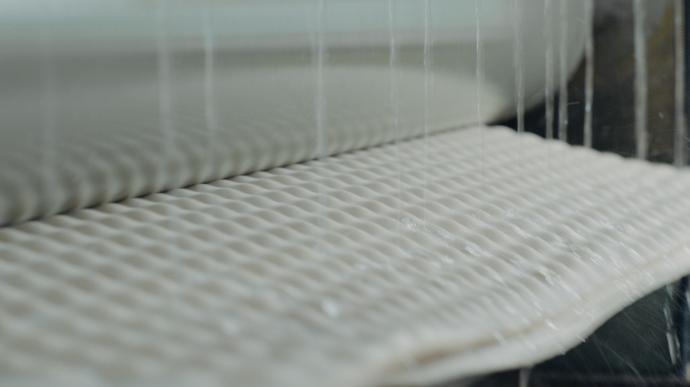

Flexible Application of Die Cutting Technolog

Our adept use of die cut technology allows us to achieve intricate patterns, textures, and perforations on NBR foam rubber, catering to diverse design requirements from different clients. The flexibility of this technique enables us to explore a broader range of design possibilities on our products, thereby offering solutions that are more creative and distinctive.

Intricate Sewing Techniques

Our team possesses excellent sewing skills, enabling us to intricately sew NBR foam rubber with other materials to achieve more complex structures and 3D designs. This delicate sewing technique not only enhances the appearance and texture of the products but also enhances their practicality and functionality.

WINBOSS Industrial Co., Ltd. demonstrates its outstanding capabilities in the field of NBR foam rubber processing through its diversified processing methods. We not only possess technology and equipment but also boast an exceptional professional team capable of providing highly customized solutions based on clients' needs. This diverse processing capability not only enriches the form and functionality of our products but also ensures their superior performance and quality. We are committed to maintaining our diversified processing advantages, offering clients a wider range of diversified and competitive products, while continuing to lead the market.